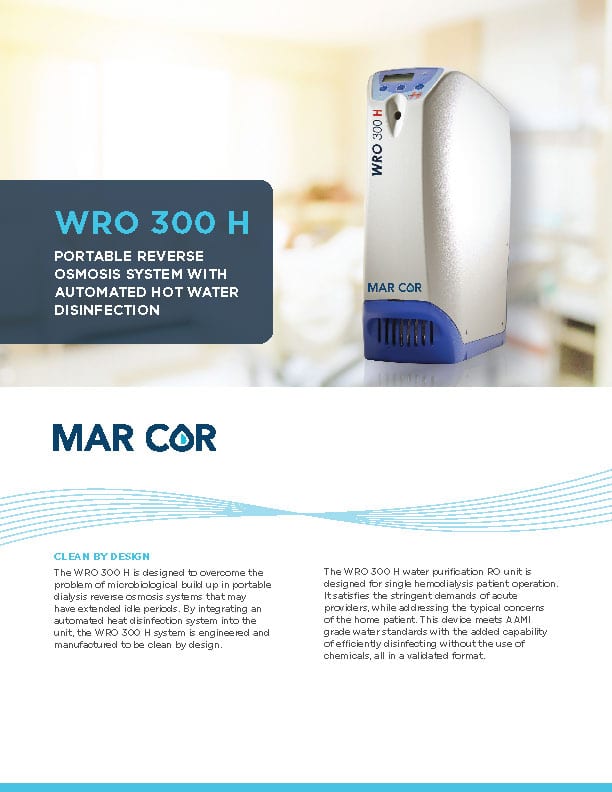

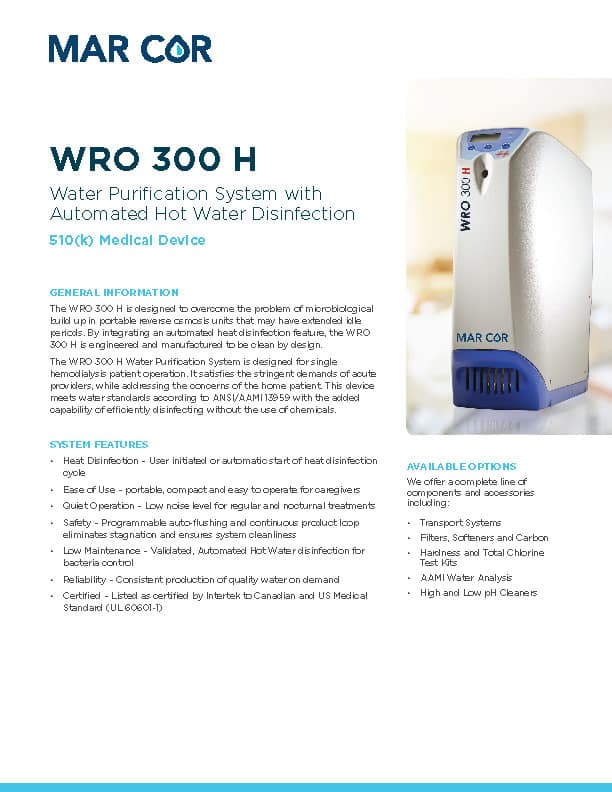

WRO 300 H Reverse Osmosis Dialysis Water System Description

The first 510(k) portable reverse osmosis water system with automated hot water disinfection. The WRO 300 H has been designed to overcome the problem of microbiological build up in portable dialysis water systems that may have extended idle periods.

By integrating an automated heat disinfection system into the unit, the WRO 300 H system is engineered and manufactured to be clean by design.

What Makes the WRO 300 H Different?

- Ease of Use – Automated procedures to minimize caregiver involvement

- Quiet Operation – Low noise level for regular and nocturnal treatments

- Low Maintenance – Validated, Automated Hot Water or Chemical disinfection for bacteria control

- Safety – Programmable auto-flushing and continuous product loop eliminates stagnation and ensures system cleanliness and readiness

- Reliability – Consistent production of quality water on demand

- Service & Support – Technical assistance, manuals, training DVDs for help when needed

Standard Features

- Portable, compact and easy to operate with a very low noise level

- Additional automated procedures and internal diagnostic minimize home patients and caregiver involvement

- Programmable automated flushing and continuous product water loop eliminate stagnation and ensures system cleanliness

- Continuous product water loop minimizes water volume requirements for purified water production

- Automated processes ensure consistency with disinfection procedures

- End-to-end disinfection with qualified dialysis machines

| WRO 300 H Specifications | |

| Part Number |

W3T577585

|

| Feed Water Supply | |

| Input | 0.8 gpm (3.0 l/min) required |

| Pressure | 20 to 45 psi (0.15 to 0.3 mPa)* |

| Temperature | 41 to 86°F (5 to 30°C) |

| Quality | Potable water shall be used. Softener followed by carbon/particle filter ensures optimum performance. |

| Product Water | |

| Output | Minimum 0.3 gpm (1.1 l/min) at 50°F (10°C) and 22 psi (0.15 mPa) outlet pressure |

| Quality | Depends on inlet water quality. If potable water is used and WRO 300 H is maintained |

| according to the manual, the following minimum rejection rates will be obtained | |

| Total dissolved salts > 96 % | |

| Bacteria and pyrogens > 99 % | |

| Drain Requirements | |

| Operation | 0.32 ± 0.03 gpm (1.2 ± 0.1 l/min) |

| Peak Flow (Rinse) | 0.8 gpm (3.0 l/min) |

| Reverse Osmosis Membrane | |

| Material | Polyamide, thin film composite |

| Configuration | Spiral wound |

| pH-Tolerance | 2–11 |

| Disinfection & Cleaning | |

| Heat Disinfection | User initiated or automatic start of heat disinfection. |

| Chemical Disinfection | Automatic dilution of disinfectant. Rinse memory forcing the rinse program to start after chemical disinfection. |

| Cleaning | Customized programs for different customer needs. |

| Power Supply | |

| Main Voltage | 100, 115 or 220-240 V +/-10%, 50 or 60 Hz |

| Main Socket | 100V: max 1500 W, 115V: max 1380 W, 220-240V: max 1850W |

| WRO 300 Dimensions | |

| Depth | Max – 20.5 inches (520mm) Footprint – 15.0 inches (380mm) |

| Width – Max | Max – 8.1 inches (205mm) Footprint – 7.3 inches (185mm) |

| Height & Weight | Max – 22.2 inches (563mm) &72.75 lbs (33kg) |

Ready to Learn More?

Let's impact human health, improve product quality, and ensure better results. Together.