SDS and PSDS Bicarbonate Systems Description

Properly providing bicarbonate solution in a cost effective manner is a challenge for hemodialysis providers. Preparation and disinfection can be time-consuming and labor intensive. Bicarbonate can corrode certain metals and painted surfaces leaving your preparation area encrusted and grimy. Furthermore, if not mixed properly, bicarbonate can negatively affect the dialysate solution.

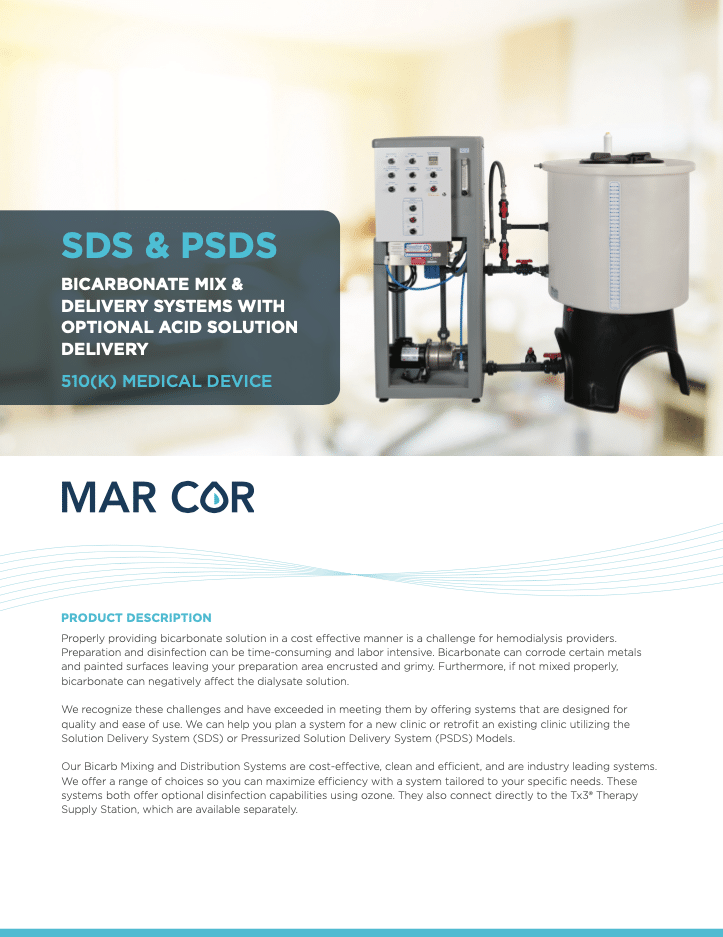

- The cone bottom tank and system frame are made of polyethylene while the enclosure and pump panels are made of polycarbonate and PVC to prevent rust and corrosion from destroying the equipment.

- Low profile 70 or 100 gallon tanks allow easy bicarbonate powder loading.

- Complete bicarbonate mixing is attained with a powerful stainless steel 3/4 hp pump system. The internal static mixer has no rotating parts to jam or break.

- Ultraviolet irradiator with a 254 nm UV lamp in bicarb fluid path to discourage bacterial growth.

- Automatic level control switch with audible and visual alarm alerts the user of low distribution concerns. Adjustable automatic level controller can be set to mix a variety of concentrates.

- Gravity feed head tanks balance the distribution and eliminate air locks and pressure spikes at the point of use.

| SDS Specifications | ||

| System Specifications | ||

| Model | Remote Head Tank | |

| Type | Mix & Distribution | |

| Capacity (Bicarb Mixing) | 70/100 gallons (265/379 liters) | |

| Capacity (Head Tanks) | 10/15/30 gallons (38/57/114 liters) | |

| Concentrates | Bicarb Only, 1/2/3 Acid(s) | |

| Electrical | 115 VAC, 20 amp, 1Ph, 60Hz | |

| Model | 70 Gallon | 100 Gallon |

| Height1 | 4’ – 10” | 4’ – 10” |

| Width1 | 5’ – 2” | 6’ – 0” |

| Depth1 | 3’ – 0” | 3’ – 0” |

| Installation Dimensons | 55” Depth x 92” Width | 60” Depth x 102” Width |

Ready to Learn More?

Let's impact human health, improve product quality, and ensure better results. Together.