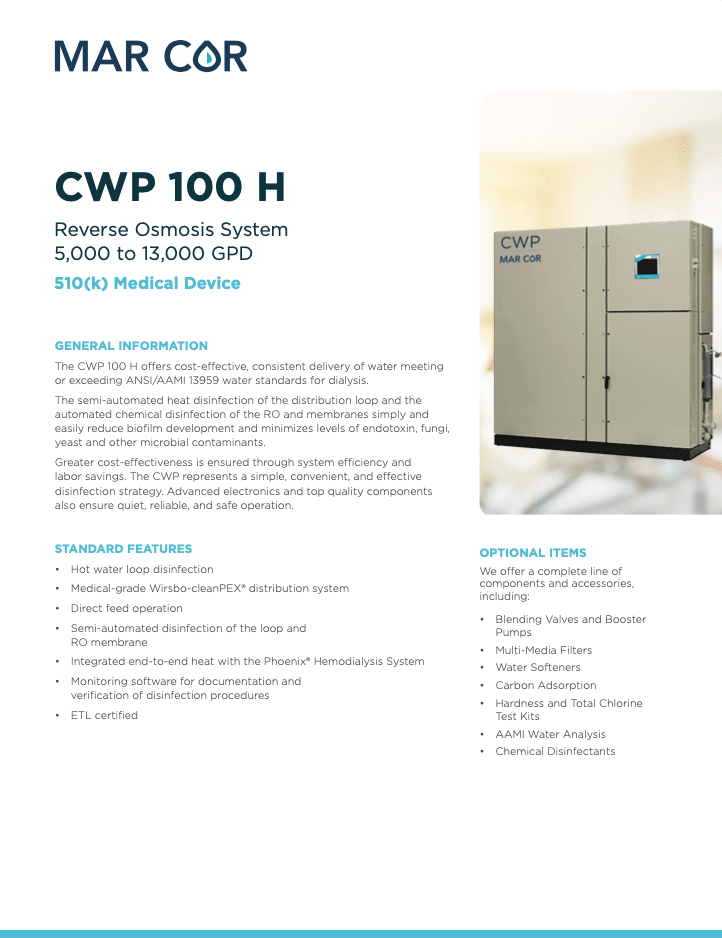

CWP Dialysis Water System Description

The CWP 100 offers cost-effective, consistent delivery of AAMI grade water, according to ANSI/AAMI 13959 for dialysis at the point of use. This system is designed to meet all current standards for dialysis quality water.

The automated heat disinfection of the distribution loop simply and easily reduces biofilm development and minimizes levels of endotoxin, fungi, yeast and other microbial contaminants.

Standard Features

- Hot water loop disinfection

- Medical-grade Wirsbo-cleanPEX® distribution system

- Direct feed operation

- Automated disinfection of the loop and semi-automated disinfection of RO membranes

- Integrated end-to-end heat with the Phoenix ® Hemodialysis System

- Monitoring software for documentation and verification of disinfection procedures

- ETL certified

Optional Items

Mar Cor Purification offers a complete line of components and accessories, including:

- Blending Valves and Booster Pumps

- Multi-Media Filters

- Water Softeners

- Carbon Adsorption

- Hardness and Total Chlorine Test Kits

- AAMI Water Analysis

- Chemical Disinfectants

| Product Water – Minimum capacity at 20˚C and at a pure water outlet pressure of 29 psi(200 kPa) | ||||||

| Output | Model |

101

|

102

|

104

|

106

|

|

| Part Number |

W3T579303

|

W3T579302

|

W3T579304

|

W3T579300

|

||

| Product Water in gallons/min (l/min) |

3.4 (13)

|

5.3 (20)

|

7.7 (29)

|

9.3 (35)

|

||

| Quality | Depends on inlet water quality. The system is designed to utilize drinking water that meets the standards of the Safe Drinking Water Act, 40 CFR. Additional pretreatment of inlet water is required. A properly maintained system using inlet water meeting SDWA can obtain the following rejection rates: | |||||

| Total dissolved salts > 95 % • Bacteria (CFU) & endotoxins > 99 % • Water conversion factor 67 % | ||||||

| Water Supply | ||||||

| Input | Model |

101

|

102

|

104

|

106

|

|

| Min Input flow in gallons/min (l/min) |

5.3 (20)

|

7.9 (30)

|

13.2 (50)

|

15.9 (60)

|

||

| Min Input pressure in psi (kPa) |

15 (100)

|

15 (100)

|

36 (250)

|

51 (300)

|

||

| Max Input pressure in psi (kPa) |

73 (500)

|

73 (500)

|

73 (500)

|

73 (500)

|

||

| Temperature | +5˚C to +25˚C* *(Maximum +20˚C if peracetic acid is used for disinfection) | |||||

| Drain Requirements | ||||||

| Peak Flow (Rinse) | Model |

101

|

102

|

104

|

106

|

|

| Required capacity in gallons/min (l/min) |

5.3 (20)

|

7.9 (30)

|

13.2 (50)

|

15.9 (60)

|

||

| Note: Maximum flow occurs during flushing | ||||||

| Reverse Osmosis Membranes | ||||||

| Material | Modified polyamide, thin film composite | |||||

| Configuration | Spiral wound | |||||

| pH-Tolerance | 2–11 | |||||

| Power Supply | ||||||

| Main Voltage | 120/208 V, 60 Hz, 3-phase (5 wires) | |||||

| Power rating | RO-unit 101-104: 1.8 kW; RO-unit 106: 2.5 kW; Heating unit 101-106: 9.0 kW | |||||

| Fuse | 16 AT + 32 AT, 16 (slow blow) or 40 AT (slow blow) one supply | |||||

Ready to Learn More?

Let's impact human health, improve product quality, and ensure better results. Together.